GF56 engine is suitable for General Aviation market (CS23 and FAR23 aircraft range).

It’s a retrofitting engine and can be installated on aircraft currently using Lycoming and Continental engines.

It’s fully designed by an internal high qualified engineers team of CMD to ensure accurate manufacturing process control, production cycle and continuity airworthiness.

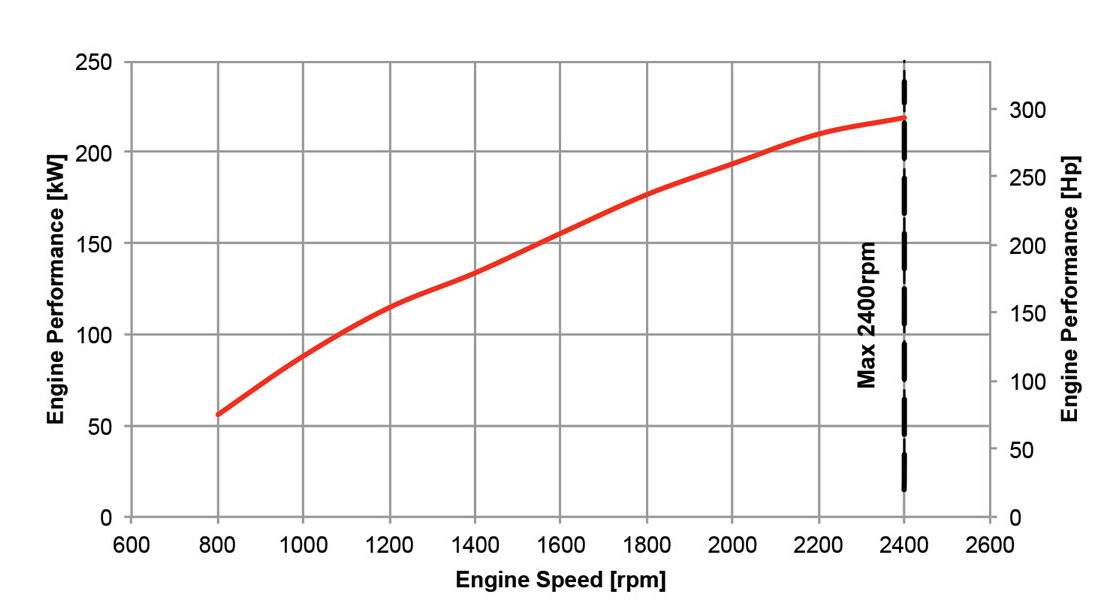

Aircraft Engines 300 HP - JetA1 / Diesel

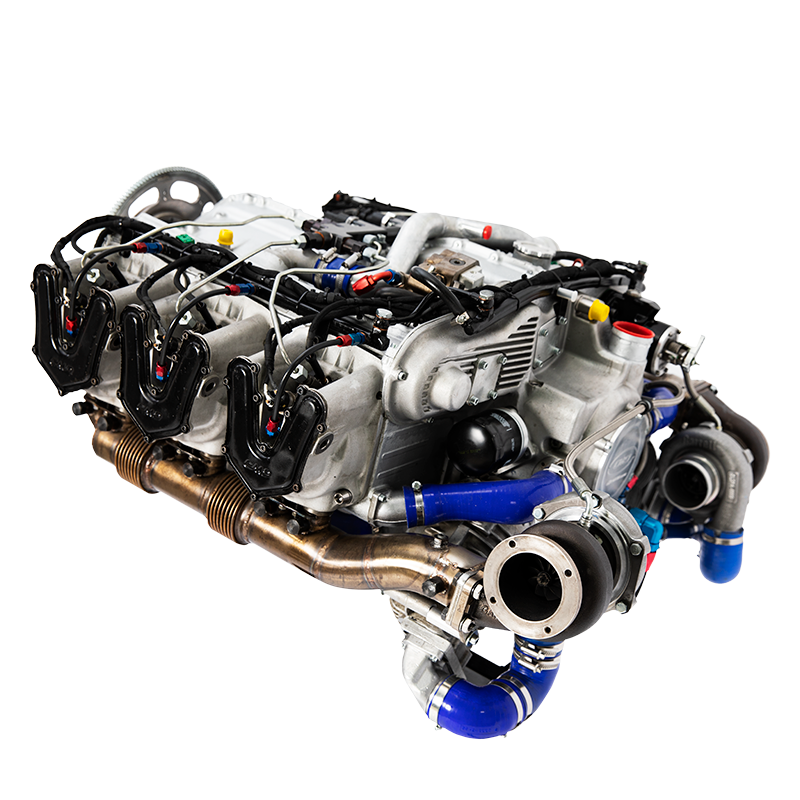

AVIO GF56 is a diesel common-rail direct injection engine, 2-strokes uniflow, 5 cylinders boxer, liquid cooling system, 5600cc., “direct drive” transmission.

General Aviation; RE-engine market; “Rotary wing” segment; Unmanned Aircraft.

GF56 is a project which has transposed all innovations available in the engines for general aviation field, while trying to always pursue an aeronautical philosophy.

The injection electronic control related to turbo-supercharging and in terms of components’ efficiency, involves the choice of liquid cooling system that, compared to air cooling, allows optimal thermal load control for disposal and better management of cooling at altitude changes.

All mechanical and fluid dynamics are made by CMD and completely independent from existing engines.

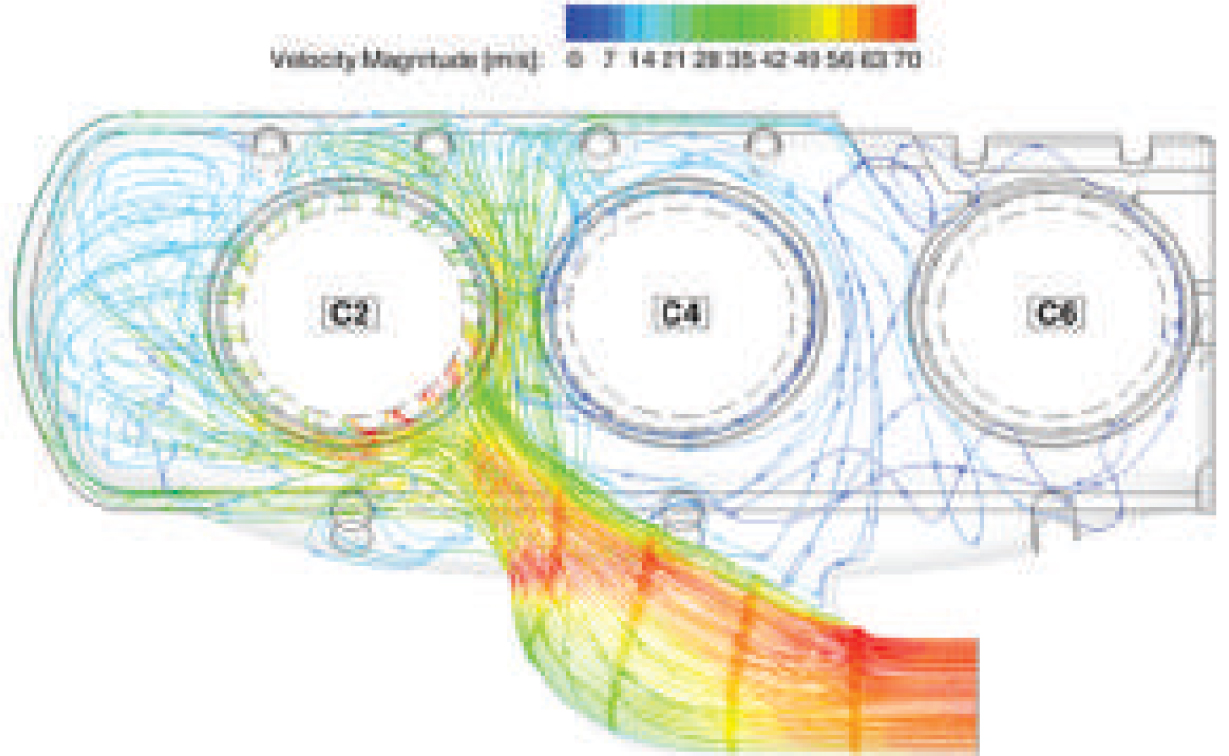

GF56 has a Roots compressor and a pressure blower per bancata which they are in series in a first phase and then in parallel. The Roots compressor just need in a first phase for washing (as two-stokes uniflow) and then the biggest contribution is made by pressure blower at a maximum power.

At maximum torque the efficiency is greater than 40% and the energy consumption is 220 g/kWh.

On the GF56 there’s our CMD FADEC - Full Authority Digital Engine (or electronic) Control.

FADEC is an automatic control system of parameters and engine perfomances. The system governs the engine work in all its operating states.

GF56 thermo-fluid dynamics is optimized and temperature and pressure peaks are limited, which ensure clear benefits in terms of Nox emissions.

Regarding noise, in addition to relatively low pressures, we must remember that GF56 is a two strokes uniflow which increasingly has more regularity a combustion for each engine ride) in terms of sound pressure changes and thus noise.

Also, the use of common-rail gives the opportunity to manage the combustion by decreasing pressure peaks for the benefit of the noise.

The liquid cooling system is an optimal solution for rotary wing applications, because allows to expose only radiant masses to airflow and does not imply the installation of forced ventilation system with fans and cowlings requiring space and are at the expense of weight.

Diesel common-rail engin

Direct injection

2-strokes uniflow

6 cylinders boxer

Liquid cooling system

5600 cc

“Direct drive” transmission

Dual fadec

5600cm3

Information related to Manuals will be available on this page soon.

For information and updates, send an email to info@cmdengine.com