For over 15 years CMD has been focused on ECU design (Electronic Control Unit) for both LPG and CNG engines and diesel and gasoline internal combustion engines.

We are also able to cover each phase of entire engineering design of diesel and gasoline control system engine.

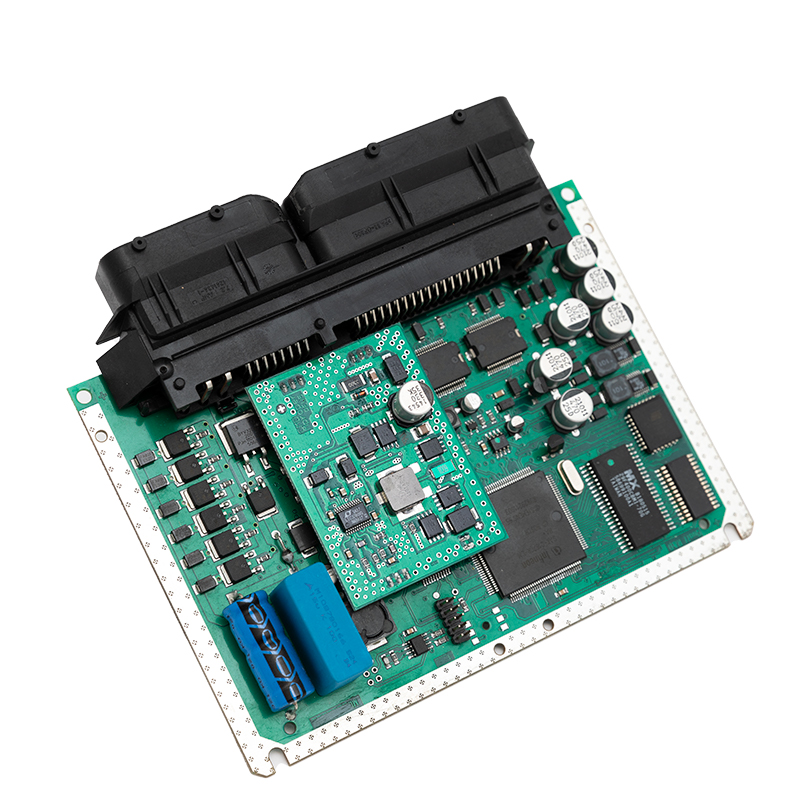

CMD designs and produces ECU for Diesel common-rail engines.

This ECU allows to make electronically adjustments on the fuel quantity injected and the fuel pressure, according to the engine operation conditions.

ECU can manage up to 6 injectors with solenoid and is supplied with self-diagnosis and strategies of emissions control.

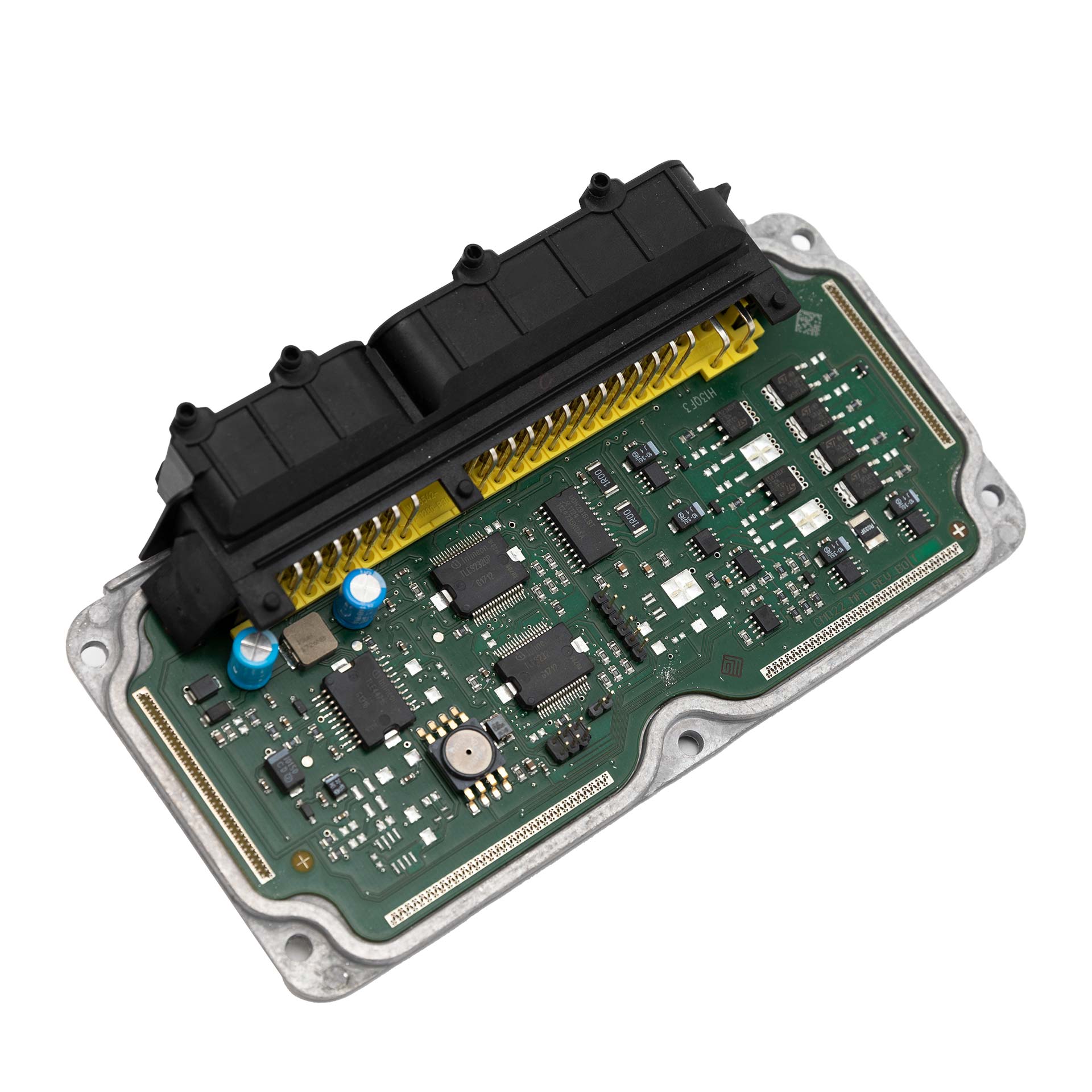

ECU controls the fuel quantity to inject and the ignition coils depending on engine operation conditions.

This ECU allows to manage electronically adjustments on the fuel quantity injected, ignition advance and the fuel pressure, according to the signals received by sensors.

CMD provides different solutions: from single-cylinders to 4 cylinders engines.

CMD has certified CMD22 gasoline engine according to EASA CS22 subpart H. CMD22 ECU has been developed by electronic CMD engineers and qualified according to DO-160G.

The Bi-fuel ECU integrates into a single control unit the algorithms for the gasoline engine CNG/LPG.

During each step of the engine operations it is possible to select the fuel to inject without any discontinuity in terms of engine torque.

CMD is investing in electric and hybrid mobility with BLUE HYBRID SYSTEM of FNM.

FNM Marine is CMD business unit for diesel marine engines production.

Electric and hybrid solutions are important resources to exploit for the pollution decrease: it is causing a climate crisis increase.

The EDR (ECU Data Reader) is the tool supplied to FNM service centers to make a diagnosis process on engines during maintenaince.

The EDR, equipped of user friendly graphic interface, is very reliable and practical, allowing to quickly and accurately find engine faults.

EDR enables to read engine parameters (RPM, throttle position, rail pressure, etc.) and to report them in order to ensure a post-analysis.

The calibration is one of most difficult phases of engine development and requires methods and tools necessary to develop a strong product and to improve the efficiency of the trials.

CMD know-how allows to have an engine operation overview for finding the best among different solutions.

Thanks to partnerships with important Research centers, today we have the cutting-edge instruments to ensure the use of experimental methods for experimental activities, thereby cost and time reduction, without affecting the quality result.

We are also able to achieve more reliable results with a predetermined confidence level.

CMD also designs and produces engines wiring, providing best solution for all needs.

The wiring project is implemented during all development steps: from feasibility study to the calculations of cable section, up to assembly.