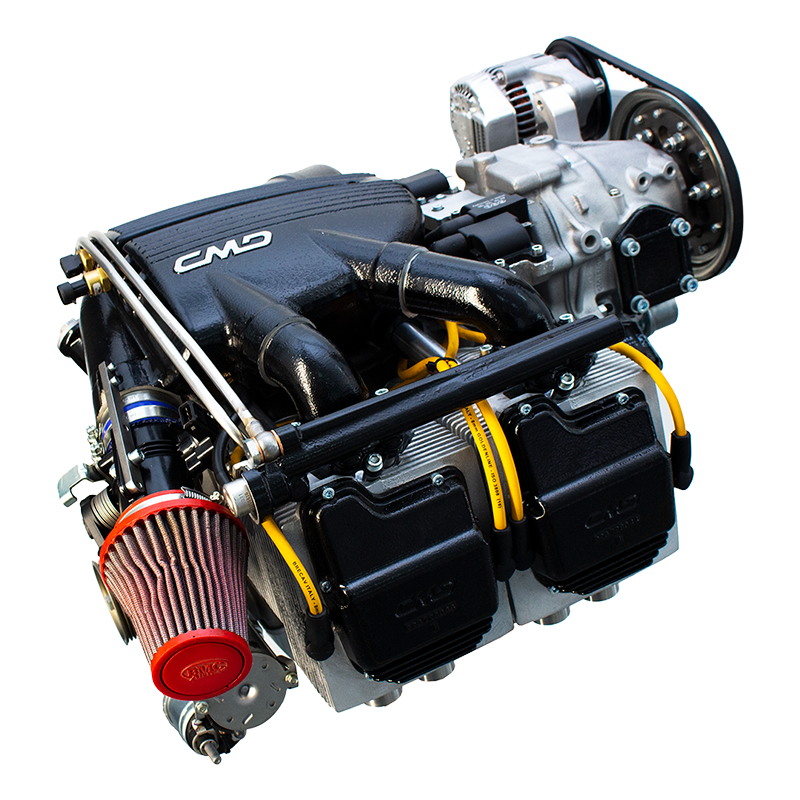

The CMD22 AVIO engine is suitable for ultralight aircrafts and VLA, LSA, CS-22 range. It’s a cutting-edge engine, low environmental impact and a high operating time.

CMD22 is an indirect electronic injection gasoline engine, air/oil cooling system, 4 cylinders boxer, 4 strokes, cycle Otto, 220cc.

CMD22 engine got a Type Certificate according to EASA CS22 subpart H (EASA E120).

The CMD22 engines are mostly used for ultralight aircrafts, tactical UAV, recreational and commercial purposes.

CMD22 engine is an entirely “Made in Italy” engine realized in our plants of Atella (PZ) and Caserta by an internal team of high skilled engineers.

In the VLA (Very light Aircraft) and LSA (Light Sport Aircraft) ranges, C.M.D. Costruzioni Motori Diesel S.p.A. is the only company to have entirely developed, designed and produced an engine totally in house, also as concerning the Electronic Control Unit (ECU), according to DO-160.

On January 2018 CMD has finished the CMD22 engine certificate, receiving the Type Certificate issued from EASA, European Aviation Safety Agency.

CMD22 is also first Italian engine certified in CS-22 range subpart H, suitable for aircrafts of CS-VLA and CS-LSA range.

In its market segment, the CMD22 engine stands out from competitors thanks to lowes stress at same power condition: the components suffer less strain by reducing engine wear.

All those characteristics can make CMD22 more eligible in terms of efficiency than the other competitors’ engine.

Gasoline engine

Indirect electronic injection system

4 cylinders boxer

4 strokes air/oil cooling system

Cycle Otto

Engine management system

Electric starter

Propeller speed reduction gearbox 1:2

Air intake system

That’s how we worked for obtaining the certificate

EASA CS 22, subpart H, chapter CS 22.1849

The engine must be subjected to an endurance test (with a representative propeller) that includes a total of 50 hours of operation and consists of 25 inclusive cycles for each cycle: 3 takeoffs, 15 minutes at the 75% maximum continuous power and 1 hour at maximum continuous power.

During the endurance test, all most representative engine parameters have to be monitored and recorded. The engine must have no damages at the end of test and no power losses with declared the fuel and oil consumption.

Information related to Manuals will be available on this page soon.

For information and updates, send an email to info@cmdengine.com

Information relating to instructions for continued airworthiness will be available on this page soon.

For information and updates, send an email to info@cmdengine.com

Information relating to service bulletins will be available on this page soon.

For information and updates, send an email to info@cmdengine.com.